-

Sustainably grown

-

Carbon sequestering trees

-

Biodegradable core

-

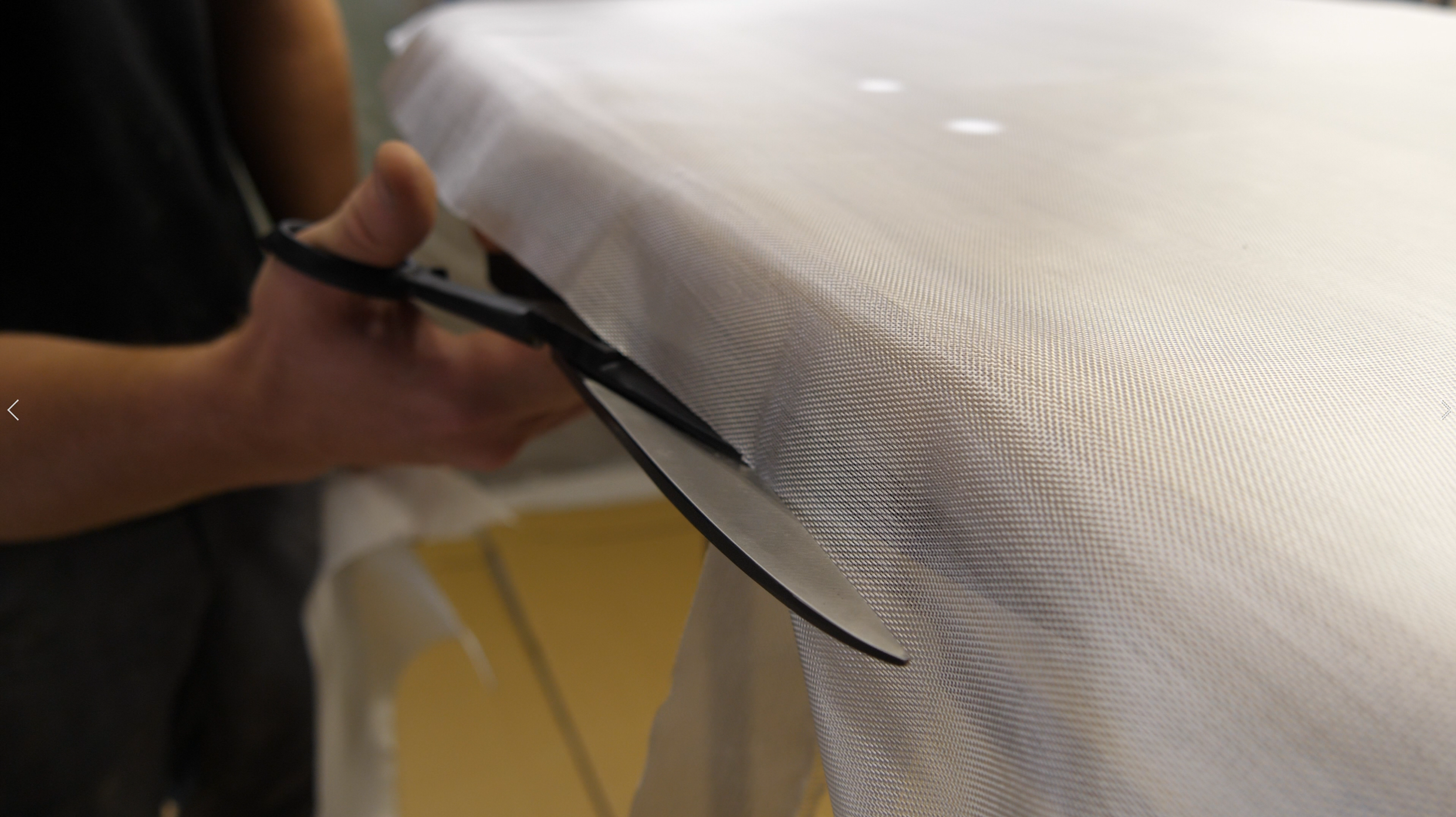

Durable

-

One third the amount of resin

-

Less than 500g of waste

Sustainable Paulownia

The core of our wooden surfboards are made with sustainably grown Paulownia timber

Paulownia can grow to a harvestable size in only six years. During this period it sequesters carbon dioxide, trapping the carbon within cellulose

This makes our surfboards more than 95% biodegradable

A Conscious Construction

The hollow wooden core replaces polyurethane foam which can be polluting and toxic

By using the natural strength of the timber, only one third the amount of fiberglass and resin is required

Every material is used with care. Less than 500g of waste is created for every surfboard

Designed for Decades

With a precise and durable construction, each board is made to last

Enjoy a surfboard that will look like the day you bought it, years into the future