The Most Sustainable High-Performance Surfboards on Earth?

In a time when greenwashing is common for the pursuit of profit, it’s becoming more and more important to measure one's impact on the environment. Measuring sustainability is extremely difficult and requires looking all the way back up one’s supply tree.

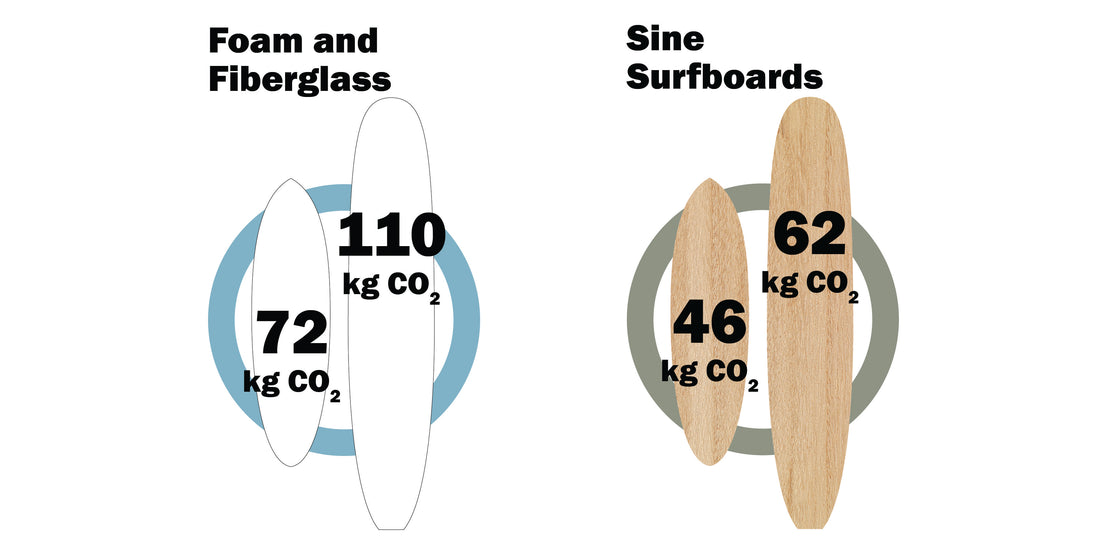

For this reason we wanted to measure our impact. To show people that we’re serious about sustainability and how we compare to conventional foam and fiberglass surfboards. Wave Changer, Carbon Halo and The University of Technology Sydney recently published one of the most complete carbon life cycle studies of surfboards. Founder of Wave Changer, Tom Wilson was kind enough to send me the spreadsheet behind the document, detailing all the calculations, so we could determine our own carbon footprint.

Note that these carbon calculations account for material, construction, waste and distribution emissions and do not include lifecycle and use emissions that occur as a result of the surfers activity.

Emissions breakdown

1. Materials Emissions

This is where we make the most carbon savings, by using a sustainable blank material and by reducing the amount of fiberglass and resin we have cut material emissions by 65%! If electrical and transport infrastructure was completely green, this would be 100%.

The Blank

Made of hollow-Paulownia wood. Paulownia sequesters carbon as it grows, with approximately 50% of the weight of wood being carbon that was previously atmospheric CO2. The production and transportation emissions were also taken into account, where shipping of the timber accounted for 7-11 kg of CO2 and wood processing at the plantation accounted for 5-8 kg of CO2 per surfboard.

The Shell

Like a traditional surfboard, we also use fiberglass with PE resin. The difference is that in our construction, the wood provides a great deal of strength, this way less fiberglass and resin is needed in the outer shell. For shortboards, 2/3rds the amount of fiberglass is needed while for longboards only 4/9ths the amount of fiberglass is needed.

2. Construction Emissions

Construction emissions are related to electrical usage during the manufacturing process and include things like CNC machining, air conditioning and tool usage. Our production emissions are higher than a regular surfboard because we take more time to CNC our surfboard blanks. Luckily our material emissions savings justify this, keeping us well below regular surfboard emissions.

3. Waste emissions

We calculate our waste emissions as a fraction of the emissions produced by a regular surfboard based on our reduced fiberglass and resin usage.

One of the great things about working with timber is that the offcuts and sawdust is all biodegradable. Our wood waste is taken in by a local compost/soil manufacturer where it is recycled. Larger paulownia offcuts are donated to a local school and mens shed, where they receive a second life in a variety of woodworking activities.

4. Distribution Emissions

We have slightly lower emissions for distribution because we currently operate in Australia only and often ship with a company that packages our surfboards in board bags and not in cardboard or bubble wrap. If we do use cardboard we make sure it’s recycled, sometimes 2 or 3 times over.

Are Sine Surfboards The Most Sustainable High-Performance Surfboards?

Of course if someone milled their own tree and made a solid wooden board finished with a natural oil, then this surfboard would have a lower environmental impact than ours. However, this surfboard would not have much value in the market because it wouldn't surf very well.

We cannot be certain, but we believe we make the most sustainable high-performance surfboards on earth! It would be a pleasure for us to discover other manufacturers with such a low environmental impact so I encourage others to undertake their own carbon analysis.

Many of these emissions are out of our control. If our electricity and transport industries were renewable, each surfboard would be better than net zero. Although, as this is not the case at the moment, we will look to work with carbon offsetting companies to make all our surfboards net zero and not just emissions reducing.