Surfboard graveyard to sustainable manufacturing

Sine Surf began when I snapped a new surfboard in 2020 on it's first surf. I took it back to the surf shop and suggested there must have been a manufacturing fault.

The owner then took me out the back of the shop, and I was shown a graveyard of over 100 snapped surfboards. He commented something along the lines 'this happens all the time, it's just how surfboards are made'.

Curious, I began researching how surfboards were made, and what durable and sustainable alternatives were available. I soon discovered wooden surfboards.

These surfboards are beautiful and can perform well if built with enough precision. Wooden surfboards are not common today because of the high material cost and the large amount of skill required to make them.

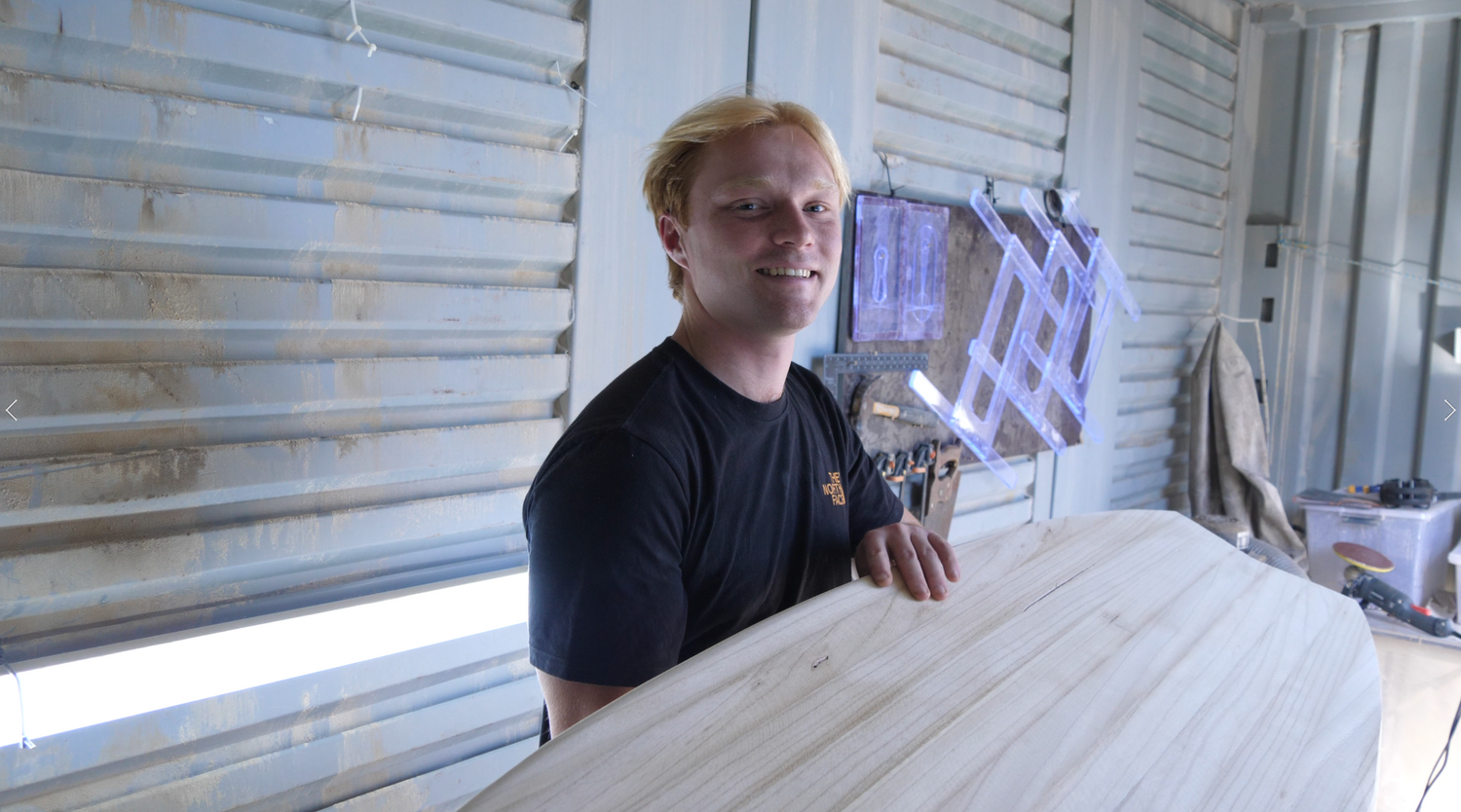

After tinkering with designs and with some new ideas on how to make them efficiently. We set about bringing wooden surfboards back into the main stream.

Early on in the journey I met Alastair who helped me give life to some conceptual designs centered around cnc machining. Alastair has since founded Sine Surf with me.

We're now able to turn any shape into a high-quality, sustainable and durable hollow-wooden surfboard.